|

See how these instrument builders are using the Carbon Fiber

D-Tube Neck Beam in their instruments... |

|

Christoph Gruber, Johannes Auly, Adam Wehsely-Swiczinsky, Frank Deimel

European Guitar Builders (EGB) - Auly Guitars • Mada Guitars • Deimel Guitarworks

At the request of Austrian guitarist and composer Christoph Gruber, the luthiers from European Guitar Builders (EGB) created the JAFmaster - an ultra-light electric guitar weighing an amazing 1.4 kg / 3lbs 1oz. The JAFmaster was built using a Gemini D-Tube neck design instead of a traditional truss rod, delivering outstanding stability, resonance, and minimal weight.

|

|

Christopher Cozad

Cozad Guitars

Christopher began building acoustic guitars in the mid-1970s. Today, Cozad Guitars produces a limited number of instruments for a select clientele from a shop located near Charlotte, NC.

|

|

Eric Aceto

Ithaca Stringed Instruments

Immersed in the traditions of jazz, acoustic folk and blues, electrified rock and experimental music, Eric has been active as a session player, touring musician and designer of musical instruments for over 40 years.

|

|

Michael Griffin

Rochester Philharmonic

Michael Griffin uniquely enjoys incorporating the insights of a professional orchestral musician in his making/repair of violin family instruments, a combination of pursuits he has maintained over thirty-plus years.

|

|

Harry Eibert

H.F. Eibert Stringed Instruments

Harry Eibert

operates a full service shop for the restoration, repair, and

construction of stringed instruments. Specializing in vintage

restorations with complete attention to detail and artistic

execution of repairs. Custom instruments are designed and built

to order. |

|

David MacCubbin

MacCubbin Guitars

MacCubbin

Guitars offers high-quality, custom handcrafted, steel string

acoustic guitars. Built for the fingerstyle player and using

only the finest materials, each guitar is individually crafted

to exacting specifications, based on years of experience and

knowledge. |

|

Scott MacDonald

S.B. MacDonald Custom Instruments

"My custom

guitars are made strictly by special order. Each is designed

around the needs, spirit and personality of the customer." |

|

David Gage

David Gage Instrument Repair

David Gage is a

one of the preeminent bass specialists in the world. He founded

David Gage instrument repair in 1978 and has a shop residing in

bustling New York city. David is multi faceted and caters to all

bass players from jazz to classical to rock n' roll. |

|

Ken Parker

Ken

Parker Archtops

Ken Parker

shook up the industry in 1993 with the Fly, the most unique

solidbody design the electric world had seen in years. For more

than 30 years now Ken Parker's primary passion has been

advancing the art and science of archtop luthiery. |

|

James Ham

Ham

Strings Music

James Ham is a

professional luthier dedicated to the repair, restoration and

new construction of violin family instruments and bows. James

Ham was the first instrument builder to install our D-Tube in a

bass. |

|

Dave Bertoncini

Bertoncini Guitars

"My instruments

are hand-built, one at a time, in my small shop, by me alone. I

strive to be different by working one-on-one with my customers

throughout the entire process, sending e-mail updates and

pictures of the entire process." |

|

Mario Lamarre

Mario Lamarre Luthier

Lamarre

specializes in making string-quartet instruments as well as

double basses (contrabasses). It was Lamarre's desire to

eliminate the risk of cracks in the heel that led to the design

of the D-Tube neck cradle. |

|

Frédéric Pons

Kopo Lutherie

"My passion for

excellence in instrument making has led me to use every material

at my disposal; many kinds of wood, carbon fiber, resins, and

metals to create superior innovations in comfort and sound." |

|

Oberlin Bass Workshop

D-Tube

installed in a bass at 2012 Oberlin Bass Workshop. |

|

Joe Hendrick

D-Tube

installed in mandolins by Joe Hendrick. |

|

Mark Frazier

D-Tube

installed in Guitars by Mark Frazier. |

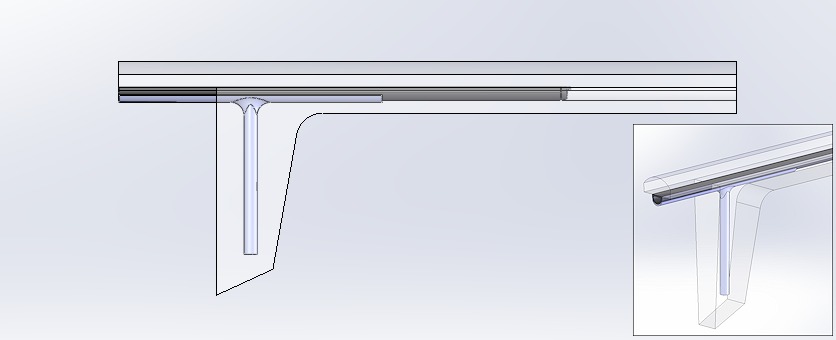

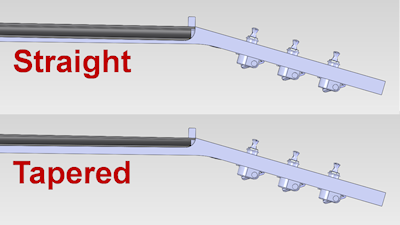

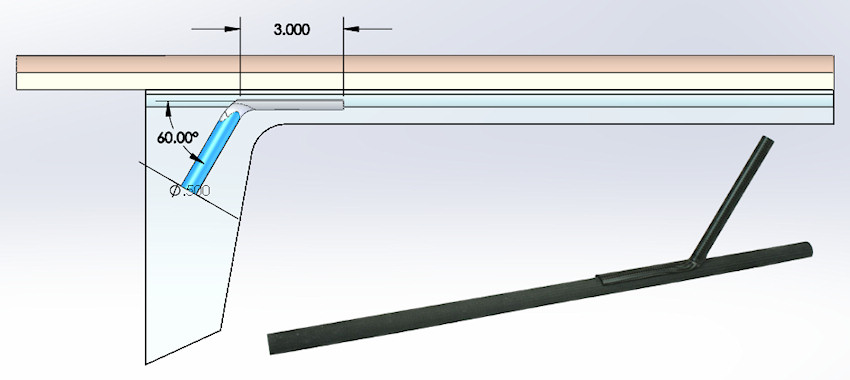

CARBON FIBER D-TUBE NECK BEAM™

CARBON FIBER D-TUBE NECK BEAM™

This product is designed to work with our 3/4" D-tube Neck Beam.

This accessory, similar to D-Tube Cradle, was developed to reinforce the heel of stringed instruments

overcoming fundamental design weaknesses due grain orientation. Tee construction simplifies installation.

This product is designed to work with our 3/4" D-tube Neck Beam.

This accessory, similar to D-Tube Cradle, was developed to reinforce the heel of stringed instruments

overcoming fundamental design weaknesses due grain orientation. Tee construction simplifies installation.